Modernization of Metal Spinning

automation even more reliable and cost-effective manufacturing option

Modernization of Metal SpinniNG

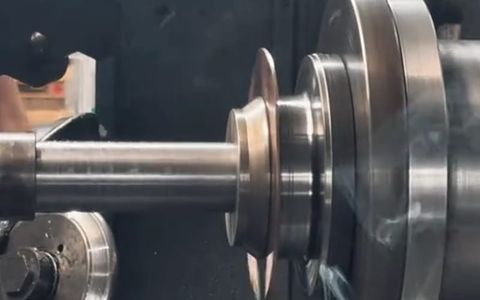

Automated metal spinning makes use of computer numerical control (CNC) in place of hand spinning. CNC is a method of subtractive manufacturing technology, which follows a computer aided design (CAD) model along with a variety of cutting tools to remove material from a blank in order to produce the desired component. The major advantages of CNC spinning over hand spinning include:

Higher level of accuracy and consistency over an entire production runThe mitigation of human error risks through the autonomy of CNC machining and reduced touches.

The necessity of fewer personnel for high capacity production runs 24/7 operation using machines, which cuts back on manpower and operating costs.

Besides these advantages, CNC metal spinning allows for the turning of a broader range of materials than hand spinning, including less malleable materials. The materials formed using CNC spinning include:

- Aluminum

- Stainless steel

- Cold rolled steel

- Copper

- Brass

This broad range of metals allows for a wider variety of manufacturing options and broadens the range of potential industrial applications which the process might serve. With CNC providing a more cost-effective option for producing parts, along with greater accuracy and consistency, it makes good business sense to incorporate it into your fabrication process when relevant to your design.

Metal Craft specializes in the manufacturing of metal components of all shapes and sizes utilizing the metal spinning process. Contact our engineering department today to see how we can assist you in completing your project with metal spinning.

English

English

Deutsch

Deutsch

العربيّة

العربيّة