Considerations

With advancements in metal spinning technology and CNC spinning machines, Wenzel can now hold tighter tolerances than ever before.

Read More

With advancements in metal spinning technology and CNC spinning machines, Wenzel can now hold tighter tolerances than ever before.

Read MoreOur commitment is backed by a Proven Process that prioritizes expedient project quoting, unmatched engineering, clear and direct communication, and on-time delivery.

Read MoreMechanical spinning is an incremental, locally formed cold processing (or hot processing) process.

Read Moreautomation even more reliable and cost-effective manufacturing option

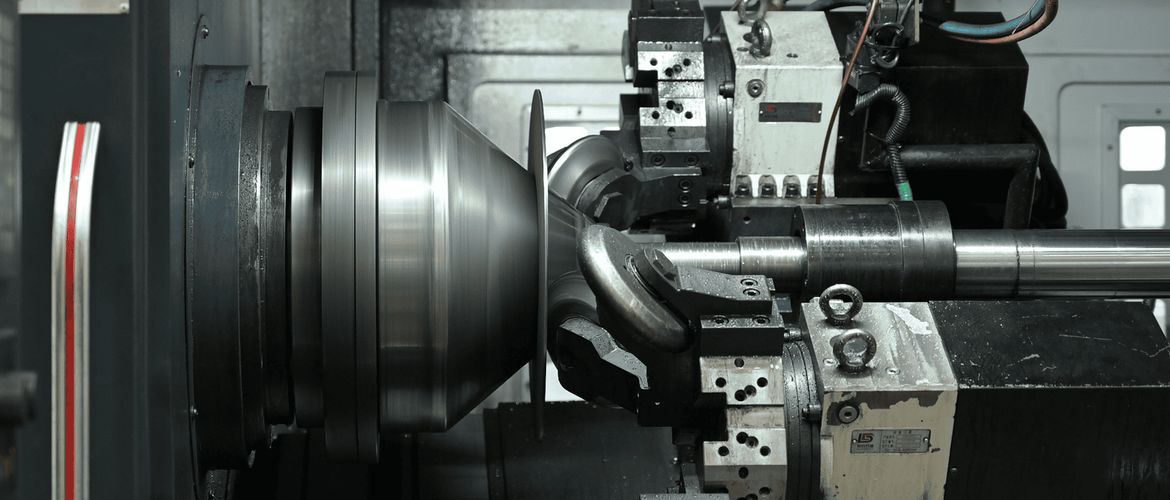

Read MoreSpin forming, also known as metal spinning, is an advanced manufacturing process that shapes metal sheets into axially symmetrical parts by rotating them at high speeds.

Read MoreWith advancements in metal spinning technology and CNC spinning machines, Wenzel can now hold tighter tolerances than ever before.

Read MoreThe metal spinning process is a forming process used to produce circular hollow metal parts.

Read MoreWith advancements in metal spinning technology and CNC spinning machines, Wenzel can now hold tighter tolerances than ever before.

Read MoreOur commitment is backed by a Proven Process that prioritizes expedient project quoting, unmatched engineering, clear and direct communication, and on-time delivery.

Read MoreMechanical spinning is an incremental, locally formed cold processing (or hot processing) process.

Read Moreautomation even more reliable and cost-effective manufacturing option

Read MoreWith advancements in metal spinning technology and CNC spinning machines, Wenzel can now hold tighter tolerances than ever before.

Read MoreThe metal spinning process is a forming process used to produce circular hollow metal parts.

Read MoreMetal Craft Spinning and Stamping produces accurate metal components that meet even the most rigorous design specifications. As a full-service company, we handle every aspect of the fabrication process from prototyping to production. In addition to our metal spinning, laser cutting, metal stamping, and engineering expertise, we also offer a comprehensive selection of value-added services. From metal polishing to welding and more, our services create customizable solutions for each project and simplify your supply chain.

Metal Polishing

Metal polishing services smooth the surface of fabricated metal components like pipes, angles, and sheets. Polishing typically provides a final finish to a metal workpiece before the material or part goes to its end use. This service delivers benefits such as:

Metal Welding

Welding, more so than soldering, forms a durable connection between metal components by bringing metals and metal alloys to their melting points for joining. Softening and expanding during heating, these metals react to high temperatures differently. They have individual strengths, levels of thermal conductivity, and melting points, necessitating multiple types of metal welding services.

Choosing the most applicable welding system for each application is essential. At Metal Craft, we are fully outfitted with the most advanced welding equipment and techniques to deliver quality products and services to customers’ specifications.

Metal Cleaning

Certain types of metal require unique metal cleaning services rather than polishing. For example, while aluminum and stainless steel oxidize easily and benefit from polishing, chrome tends to resist severe oxidation. As a result, even the best polishes are typically ineffective at removing scratches from chrome.

The hard, thin surface of metal like this benefits much more from a thorough, careful cleaning. uses state-of-the-art equipment to effectively clean metal components without damaging them.

Metal Painting

Painting fabricated metal components not only creates attractive finishes but also provides a protective coating that prevents corrosion. Many types of metals, such as steel, aluminum, and brass, draw oxygen to their surface, creating an oxide film. As the surface of these metals oxidizes, the metals dull, develop a patina, or rust.

Paint bonds to the surface of these metals and act as a surface treatment that prevents oxidation from occurring. Prior to painting, the surface of the metal requires cleaning and, depending on the material, prepping with a rust-inhibiting primer. Then paint can be applied by brush, roller, dipping, or spraying.

If your metal component requires painting as a finishing process, We will ensure your metal pieces receive high-quality, lasting finishes.